“Packing” and “gasket” are commonly used for sealed stainless steel containers and for connections to piping and peripheral components.

Because they are consumables, it is necessary to change them at the appropriate time. How often do you change the container?

The actual replacement time varies by the frequency of use and the contents, so this time we have summarized the general replacement guidelines for the silicone rubber seals [PQA] [PQB] [PQL] that come with standard airtight containers of our company.

Replacement guidelines for packing and gasket

When degraded

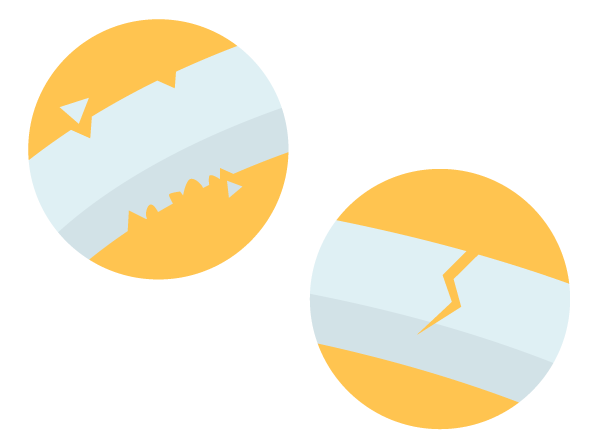

Is the packing worn out, broken or chipped?

If the packing is damaged, it may cause foreign matter to get mixed in, so please replace it with a new one immediately.

In addition to the cause of foreign matter, it can also cause leakage of contents or loss of sealing.

When discoloration happens

Our company's silicone gasket turns yellow during normal use.

This is inevitable because of the influence of ultraviolet rays and the deterioration of the material itself.

In addition, there is a case that the color is transferred from colored contents.

This may cause contamination such as color transfer to other contents.Also, if mold is generated, the marks can't be removed.

In this case, it will be a hygienic problem, so you need to replace it with a new one immediately.

When it smells bad and or the odor cannot be removed

The packing smells easily. If you handle a product with strong odor, the odor may spread to the packing and remain even after cleaning.

If the packing is used for other containers, the odor on the packing may be transferred to the contents.

When deformed or distorted

Also, if you use a deformed or stretched packing, the sealing performance will be decreased.

* The distortion of packing caused by aging may be adjusted by putting it in hot water.

Measures to be taken before problems occur

Determine the cycle of replacement

If the product is replaced after foreign matter or contamination occurs, the loss will be large.

Check that if there is no damage on the seal before use.

We recommend you to decide the replacement time of consumables in advance and replace them regularly.

For example, replace every 6 months, replace every usage cycle, replace after 5 uses, etc.

Check the compatibility with packing materials.

If the packing material is not suitable for the contents, it may swell (becoming a gnat by absorbing contents) or deteriorate quickly. So, use suitable packing material for each contents.

In addition to silicone rubber, our company also offers FKM (fluorinated rubber)/EPDM (ethylene propylene rubber)/NBR (nitrile rubber)/CR (chloroprene rubber). * The color will be black.

【PQA】PTFE (fluorinated resin) is also available. > PTFE storage container with packing [CTH-PTFE]

Use colored packing

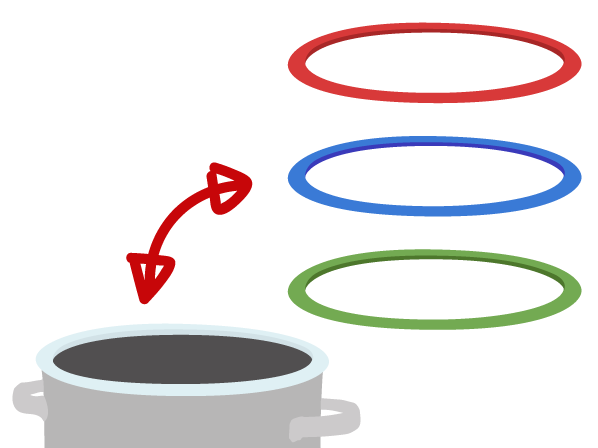

We offer type A colored silicone packing [PQA-RE/BL/GR] based on [PQA].

There are three colors, red, blue and green, which are suitable for different use.

When the packing is broken or mixed, it is easy to see where it is broken because it is colored.

If the packing color is different to the color of contents, it will be easy to find even if broken pieces get mixed in.

As measures against color transfer and odor transfer

We strongly recommend you to use it as a special packing by changing the color of the packing depending on the contents. It can prevent color transfer to other contents and odor transfer.

For the management of packing

The color of the packing can be changed and identified depending on where it is used and when it is introduced.

Tag Related Posts

- No related posts.