As you may have experienced if you have already used our stainless steel containers, the lid of the container may occasionally fail to open.

The most common cause is the difference in air pressure between the inside and outside of the container. When the temperature inside the container is cooler than when the lid is closed, the inside of the container becomes depressurized, and the lid will not open in any way.

This phenomenon has been introduced in a previous column, but this article focuses on the actual situation in which the lid fails to open due to the difference in atmospheric pressure and how to deal with the problem.

CONTENTS.

1. why does the lid stop opening in the first place?

2. how the lid looks when the contents have cooled down

3. how to open a stuck lid

4. summary

1. why does the lid stop opening in the first place?

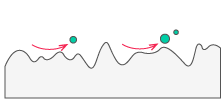

When a container is filled with a liquid or other substance and then the contents cool down, the lid will not open. Again, this is caused by the difference in air pressure between the inside and outside of the container.

This is the same phenomenon that occurs in everyday life when the lid of a bowl becomes stuck.

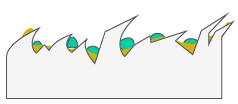

As the inside of the container cools with the lid closed, the water vapor inside the container gradually cools and returns to water.

In addition to this, the air inside the container will lose its balance with the atmospheric pressure outside the container due to the property of air that its volume decreases as it cools.

Thus, the lid cannot be opened when it is pushed by a relatively strong force from outside the container.

2. Appearance of the lid when the contents have cooled

We actually tried to reproduce the phenomenon of being unable to open the lid.

First, fill our lever-band and catch-clip type containers about 1/7th of the water and bring it to a boil. Then, the lids are immediately closed and cold water is applied from the outside of the containers for about 10 minutes to cool them.

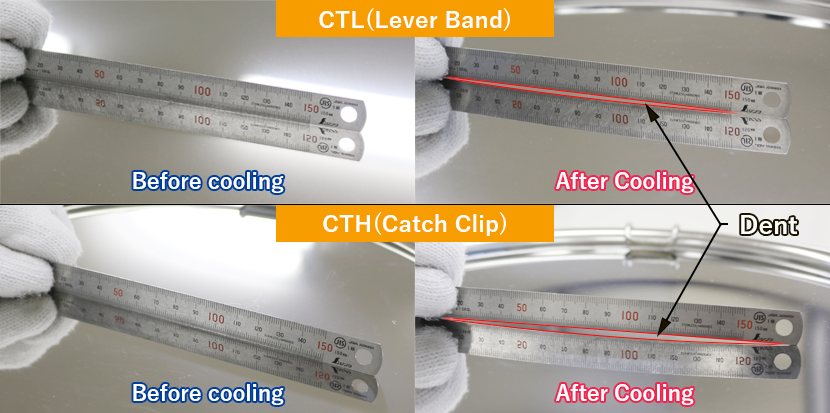

When the inside of the container is thus cooled, the lid is pushed with strong force from outside the container as explained earlier. If you actually look at the lid, you will notice that the center of the container is indented more than normal.

We placed a straight scale on the center of the lid to check the dent.

With this amount of pressure, the lid will not open even if you pull it forcefully. In the first place, it is not desirable to open the lid by force, since the contents may spill out.

3. how to open a stuck lid

So, how do you open the lid?

The following is an explanation for each lid shape.

For lever band type...

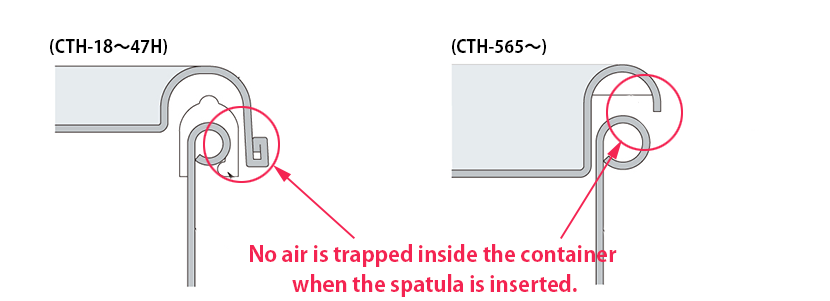

With the lever-band type, the lid can be opened by inserting a microspatula between the packing and the body, allowing air to enter the container.

Just as when opening the lid of a bowl, the lid will open if air is allowed to enter the container and the air pressure inside is equal to the air pressure outside. The details are described below, but unlike CTH, it is relatively easy to open the lid as long as you have a spatula.

Incidentally, the temperature of the contents (water) when the container was opened was 33.6°C.

For catch-clip type

In the case of the catch-clip type, its shape makes it difficult to open with a spatula. If you try to force it in, you may damage the packing or lid, or even the spatula itself.

If you want to open the lid of the CTH, heat the container to restore the air pressure inside the container. You can also wrap it in a warm towel or boil it in hot water, but this time we will heat it over an open flame.

In this experiment, the lid was closed immediately after boiling, so we waited for a while until the temperature reached that level. The lid did not move at the beginning of heating, but when we heard a rumbling sound from inside, the lid opened easily. Since the boiling point decreases in a depressurized state, the lid opened at 86.6℃.

4. Summary

If you are having trouble opening an existing container, try one of the following methods

- CTL (lever band type): Insert a spatula-like object to let air in.

- CTH (catch clip type): Heat the container to the temperature at which the lid was closed to restore air pressure.

If you are planning to purchase a container from now on, you can easily open the lid by installing a valve or air vent hole on the lid. We can also provide the microspatulas mentioned earlier.

If there is a possibility of putting warm contents into the container, please consider these measures.