The SDGs adopted in September 2015 are probably familiar words to many people today, more than 5 years after their adoption. In addition to large companies and local governments, a growing number of small and medium-sized companies are stepping up their efforts to address the SDGs.

The SDGs stand for “Sustainable Development Goals” and represent 17 goals that all of humanity should strive for by 2030. It's already 2021. With less than 10 years remaining until 2030, the target year for achieving the SDGs, the United Nations has designated the 10 years from 2020 to 2030 as the “10 Years of Action,” calling on the entire world to further strengthen its efforts.

In this article, we explain the basics of the SDGs and Nitto Kinzoku Kogyo's vision of contributing to them.

Contents

1. What are the SDGs?

1.1. SDGs = Sustainable Development Goals

1.2. What is the difference from the MDGs, the predecessor of the SDGs?

2. Our company's Contribution to the SDGs

2.1. Stainless steel is a 100% recyclable material

2.2. Stainless steel has a long service life

2.3. Contributing to the production of safe medicines in sanitary containers

3. Initiatives for Sustainable Development Goals (SDGs)

1. What are the SDGs?

1.1. SDGs = Sustainable Development Goals

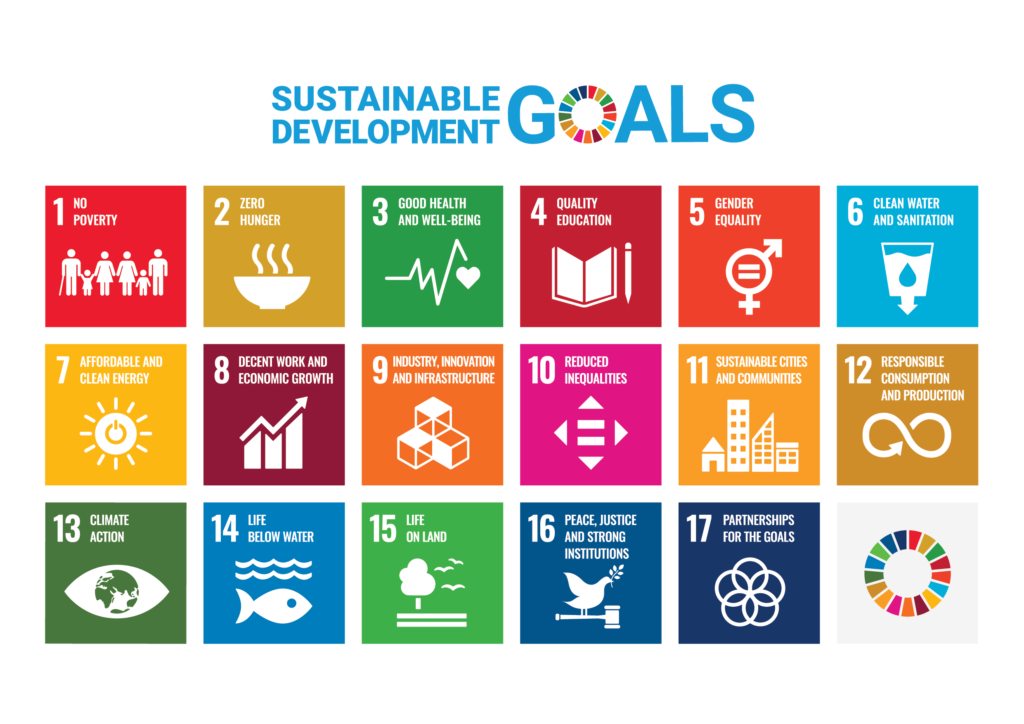

The SDGs are the Sustainable Development Goals adopted at a UN summit in September 2015. It consists of 17 goals and 169 targets. It was adopted unanimously by the 193 member states and is a common goal that the whole world and all mankind should aim for during the 15 years from 2016 to 2030. Our philosophy is to leave no one behind.

As the word “sustainable “suggests, the world today is not sustainable. If we continue to develop, produce, and consume as before, humanity and the planet will not survive. All countries recognize this and sustainable development is required to prevent it.

What is sustainable development?

It means “development that satisfies the needs of future generations but also satisfies the needs of current generations.”

In other words, it means moderate development that can satisfy the needs of the current generation without creating a shortage in relation to the needs of the future generation, while balancing social, economic and environmental factors.

1.2. What is the difference from the MDGs, the predecessor of the SDGs?

Concerns about social, economic and environmental sustainability are nothing new. The Stockholm Declaration, adopted in 1972 as a framework for promoting environmental conservation, is regarded as the first international agreement to address the relationship between society, economy and environment.

Later, in 1987, the World Commission on Environment and Development (United Nations) first created the concept of Sustainable Development, and since then, international conferences on sustainable development have been held at regular intervals.

The Millennium Development Goals (MDGs) were adopted at the UN Millennium Summit held in 2000. The MDGs are targeted to be achieved by 2015, with a total of 8 targets and 21 targets.

While the MDGs have been praised as “the most successful anti-poverty effort in history” for their effectiveness in reducing the number of poor people in the world by more than half, they have also left some issues to be addressed. New challenges are also emerging that go beyond the framework of the MDGs, such as climate change and global environmental degradation.

Therefore, when the term of the MDGs expired in 2015, the SDGs became a new goal in succession. The SDGs differ from the MDGs in the following ways:

・Developed countries will also engage in

->While the MDGs focused on solving the challenges of developing countries, the SDGs expand the goals and allow developed countries to address common challenges.

・ Not only the government, but also the private sector and individuals

->While the MDGs were largely driven by government, the SDGs involve all stakeholders (countries, businesses, the general public, etc.).

・ An integrated form of economic, social and environmental issues

->It comprehensively addresses the three elements of the economy, society and the environment and sets 17 goals. Each goal is interconnected.

In other words, the SDGs are common goals for all of humanity that each of us, as a party, must work towards so that the world and the planet can continue to be better for ourselves and our children and grandchildren.

2. Our company's Contribution to the SDGs

We believe that the following are the greatest contributions Nitto Kinzoku Kogyo can make to the SDGs.

“Continuing to provide high-quality, clean stainless steel containers to the world”

And of course,

Thoroughly turning off lights in unused areas and optimizing set temperatures based on air-conditioning operating standards (Goals 7, 11, 13)

Promoting paperless use by introducing business applications (Goal 12)

Establish maternity, paternity leave and shorter working hours systems, and promote reduction of overtime hours (Goals 5, 8)

and other initiatives, but what our company excels at and can make an impact on more people through our company's business is continuing to provide high-quality stainless steel containers.

So how does continuing to provide stainless steel containers contribute to sustainable development?

2.1. Stainless steel is a 100% recyclable material

A Yale study found that 85% of stainless steel products are recycled after they reach the end of their life. The recycling rate for industrial machinery is as high as 90%. In addition, the recovered stainless steel is 100% recyclable, which helps conserve resources and energy.

Recycling can be costly and sometimes unprofitable depending on the material. If it's not profitable, the recycling system itself becomes less sustainable.

However, even if stainless steel products reach the end of their lifespan, their inherent value as stainless steel material does not diminish. Therefore, the scrap value of stainless steel is relatively high, which is a characteristic feature.

Since the stainless steel recycling system is beneficial for buyers, users, manufacturers, and the environment, it can be said that the recycling system itself is also sustainable.

Nitto Kinzoku Kogyo's Stainless Steel Containers are the "Material Itself"

Our stainless steel containers are basically made of all stainless steel (SUS304, SUS316L, etc.). Although resin and other materials may be used as components of the product, they are often detachable.

Because the container itself is made of stainless steel, there are no “extra things” attached during the recycling process. It can be recycled as it is.

2.2 Stainless steel has a long service life

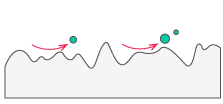

Stainless steel is characterized by its rust resistance and durability. Moreover, maintenance is low-cost, as basic cleaning and wiping are all that is required.

Even if a recycling system were established, it is best for the environment to not produce more than necessary. Stainless steel is a long-lasting material, with an average lifespan of 25 years for industrial machines and products made of stainless steel.

2.3 Contributing to the production of safe medicines in sanitary containers

Nitto Kinzoku Kogyo's stainless steel containers are used in pharmaceutical manufacturing facilities, among other applications. This is not just because of the high corrosion resistance of stainless steel or its compatibility with autoclave sterilization and disinfection.

Our containers use specially ordered BA material, which allows us to form products without performing unnecessary processing or causing damage through welding. Furthermore, as our commitment to quality, we only perform minimal buff polishing.

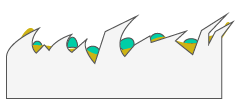

In general, buff polishing is applied to stainless steel containers to increase their gloss and smoothness. This process involves applying polishing powder, called abrasives, to the buff and then polishing the surface. However, this process leaves oil from the polishing agent in the fine scratches on the stainless steel surface that are inevitably produced during polishing. In other words, the more polish is applied on the surface, the more dirtier the surface would be.

Therefore, at our company, we use carefully selected custom BA materials with a very fine surface roughness from the state of the material. With this, there is no need to polish more than necessary. By providing clean stainless steel products, we contribute to the production and dissemination of safe pharmaceuticals, food, and other products.

Electropolishing for even cleaner stainless steel products

Electropolishing is a surface treatment widely used in the production of tanks and other equipment for pharmaceutical factories. Electropolishing is a polishing method that dissolves metal ions from the metal surface to smooth it.

By subjecting stainless steel to electropolishing, it is possible to remove small surface contaminants and prevent the accumulation of dirt by making the surface smoother. It also creates a stronger passive film, improving corrosion resistance.

Our company has the equipment and technology to perform pharmaceutical-grade electropolishing in-house. This is useful in the production of products that require high levels of cleanliness.

3. Initiatives for Sustainable Development Goals (SDGs)

As the target date for achieving the SDGs is less than 10 years away, the United Nations has launched the “Decade of Action” to call for further efforts to strengthen the SDGs. In response, countries, municipalities, and various companies are making further efforts, but the crucial point is whether these efforts themselves are “sustainable”.

In the past, the environment and development (economic growth) were considered opposing forces. However, the SDGs consider them to be coexisting and something that should be coexisted. The economic-social-environmental relationship is not a trade-off, and how to align these three elements is important.

Therefore, it is essential to work towards sustainable SDGs. Even after 2030, we must always consider sustainable development. We cannot make efforts towards the SDGs a one-time thing.

Honestly, our company still faces challenges in terms of our efforts towards the SDGs and understanding within the company. However, in order to contribute to the economic-social-environmental aspects through our business and fulfill our social mission, our company will continue to provide high-quality and clean stainless steel products to society.

References

・ステンレスとCO2:事実と科学的観察, ISSF, 2019

・The Global Life Cycle of Stainless Steels, Team Stainless & Yale University, 2021

・リサイクルが容易なステンレス鉄鋼, ステンレス協会, 2001

・青柳仁士『小さな会社のSDGs実践の教科書』, 翔泳社, 2021