Participated in the ACHEMA exhibition

Nitto Kinzoku Kogyo exhibited at ACHEMA 2022 in Frankfurt, Germany.

The exhibition was held for five days from August 22 to 26, 2022.

Thank you for visiting our booth.

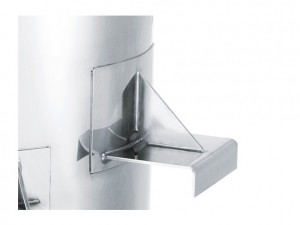

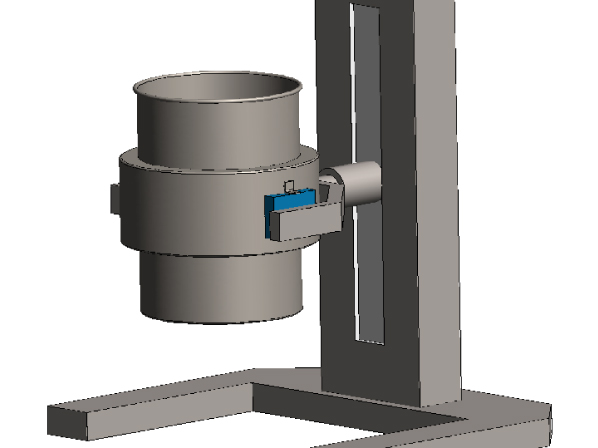

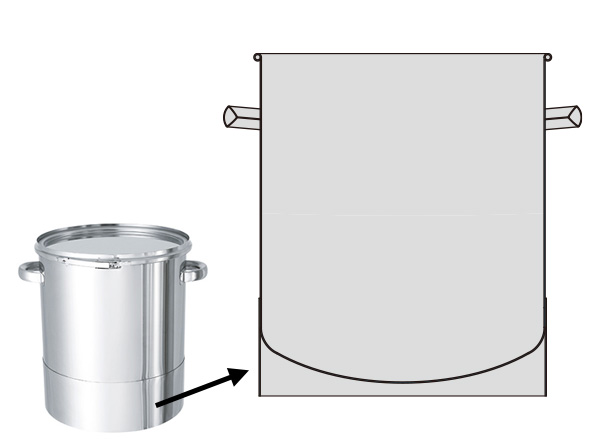

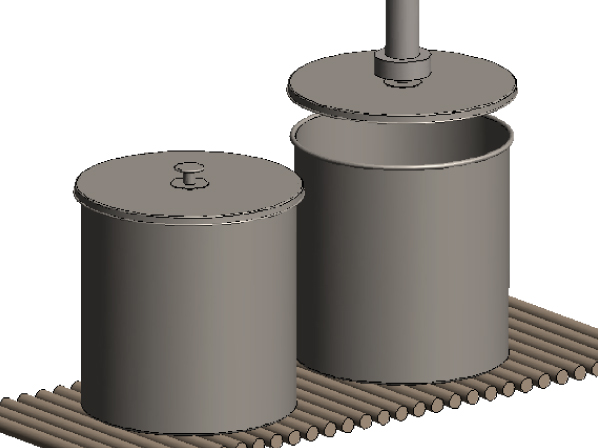

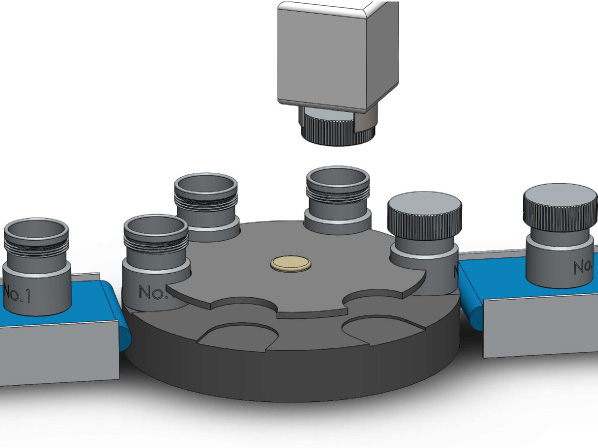

In the exhibition hall, our agitator and BEAG, which reduces foaming, attracted a lot of attention from our customers.

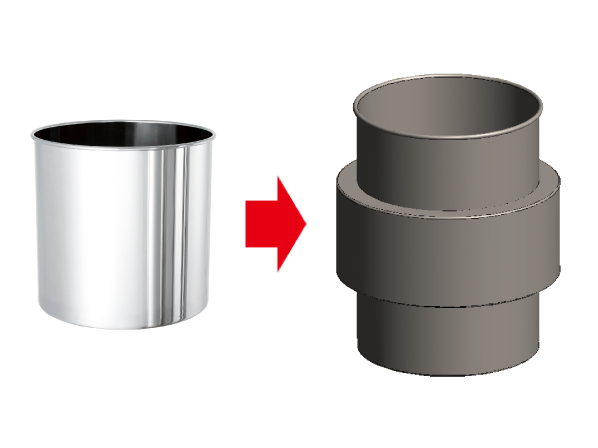

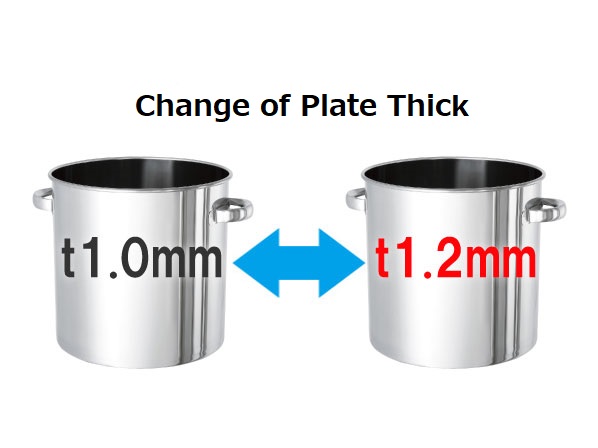

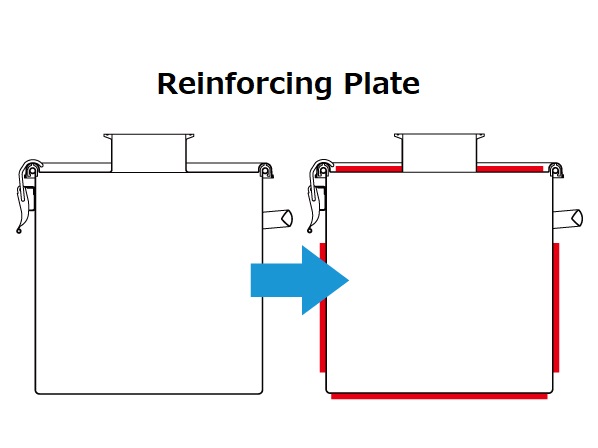

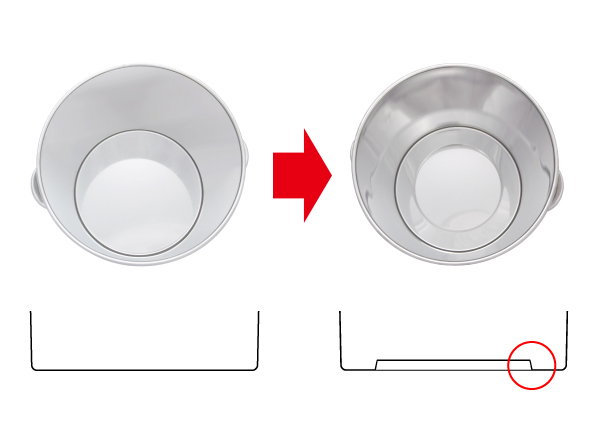

We will continue to send out information so that we can deliver our products, which consist of a stainless steel container and agitator as a unit, to our overseas customers.

We are looking for a distributor, and we are looking for a distributor who is interested in our products.

If you are interested in becoming a distributor, please contact us.

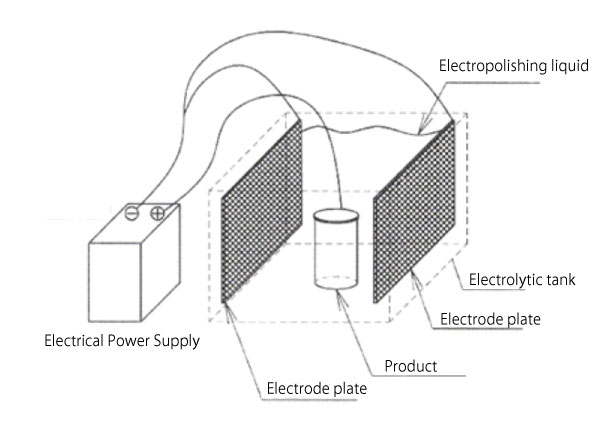

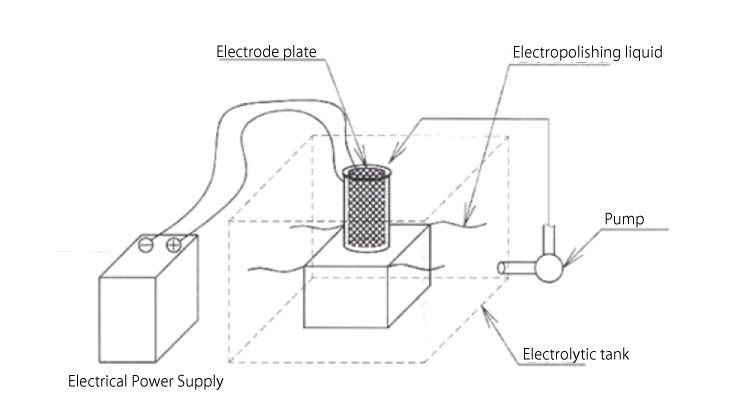

Products exhibited at the show