2L reduced pressure filter for stainless steel test

Features

The existing glass filtration system does not have enough capacity."

I want to use my own polyethylene bottles to collect the filtrate."

This product is customized based on these requests.

Suction filtration of ~2L at a time is possible.

purpose

Ceramic raw material filtration

The product on which it is based

QR-100M: Suction filtration container

Point

- Although larger in size than standard glass laboratory filters, they are made of sturdy stainless steel for safe handling.

- Reinforcement is added to the bottom of the container to prevent tipping over.

Engineering Staff Comments

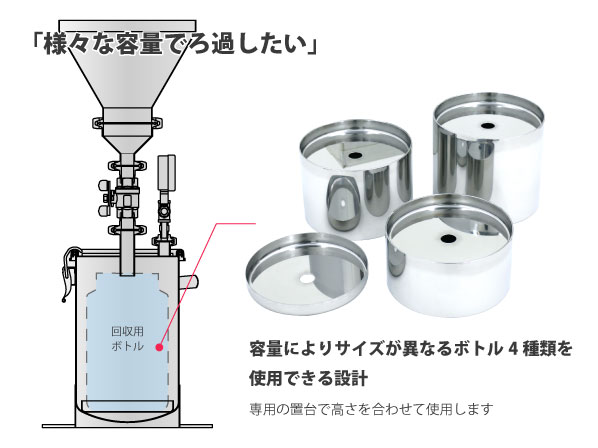

More compact than standard ones for handling in small quantities. The specifications are compatible with all four types of customer-owned small-volume polyethylene bottles (0.25L, 0.5L, 1L, and 2L).

The filter section is sized to match the filter paper conventionally used.

Custom-made services are available, such as changing the size of the filter, filter section, and filtrate receiver container.

Sales Staff Comments

We were able to make proposals and improvements to the dissatisfaction of the facilities we had been using, in accordance with our budget.

Product Specifications

[Material]

Body (hopper / container): SUS304

Filter (catch net): SUS304

Hopper's temporary stand: SUS304

Packing: Silicon rubber (Food Sanitation Law Compatible)

【Other specifications】

Ryokan installation part: about φ90mm (3.5S Helle)

Proollable capacity: ~ 2L

Surface treatment: Inner and outer buff polishing

Usage conditions: Decompression specification (-0.1MPa)

Management number: 1Y001419

Details & Notes

Original Product

Other “Suction Filtration” Examples

Pressure-Adjustable Container with Baffle Rotator

Delivered to an Electrochemical Materials Manufacturer.

It is also compatible with pressurization.