Powdered body measurement / reversal introduction unit

Features

Example of adoption in the food industry

This unit is used for weighing and feeding powder.

This unit is used in the process of weighing confectionery ingredients (powder) and feeding them into a sieving machine.

The set includes a hopper with a dust collecting hood, a dust collector, a receiving container, a scale, a cart, a lid for inverted feeding, and a lifter.

A dust collector is connected to the dust collecting hood to collect the dust that is blown up when powder is fed into the sifter.

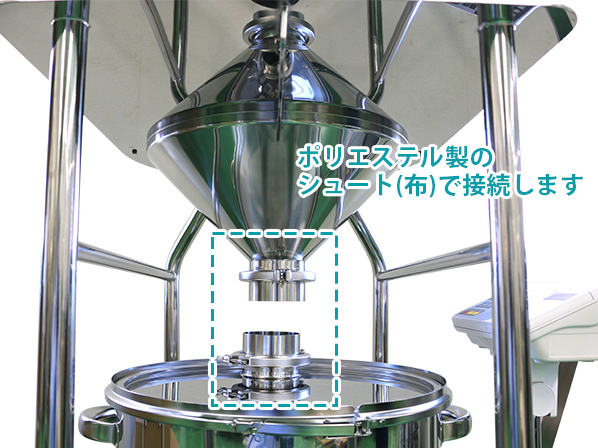

The hopper and receiving container are connected by a polyester chute (cloth).

A stainless steel cover and receiving vessel are installed on the top plate of the scale.

There is an air intake at the bottom of the receiving vessel for inverted feeding.

How to use

Load material into the hopper equipped with a dust collecting hood.

Weigh the material accumulated in the receiving container at the bottom of the hopper with a scale installed below the container, and store it.

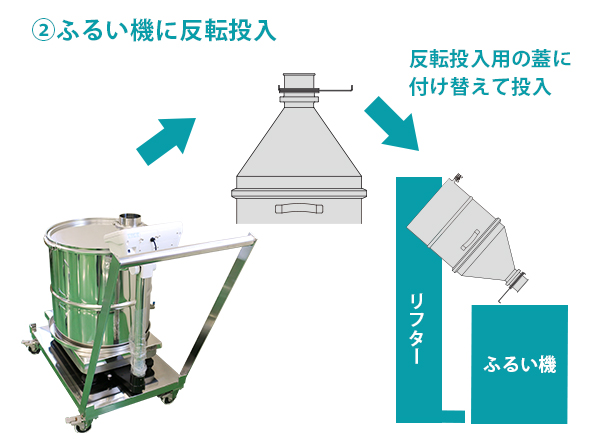

Replace the lid of the receiving container with a lid (with a valve) for inverted feeding.

The lifter inverts the receiving container and feeds the material into the sieving machine.

Sales comment

This was a new installation at a new factory. The user wanted an all stainless steel machine. We were able to propose a hopper, dust collector, container, and lifter made of stainless steel within the budget, and the customer adopted our proposal.

Product Specifications

specification

Hopper, receptor, bogie material: SUS304

Dust collector / lifter: stainless steel

Hopper dimensions: width 580mm x depth 850mm x total height 1567mm

Container dimensions: Inner diameter 470mm x height 468mm (when no lid)

Management number: 1x011764

unit content

・ Hopper with dust collection hood

→ hopper under the hopper based on htd-l The hopper part has been shortened to secure the lower height.

・ Dust collection machine

→ Made of stainless steel

・ Pacific container

→ Based on The exit has been changed to 100A Helur, and the hopper angle has been changed to 70 °.

→ Valve: sh-100a .

・ A scale

→ The measuring dish is made of stainless steel

・ Bogie/lifter

→ Made of stainless steel