KTT-CTH : Single-Tapered Sealed Container Clip Type

Features

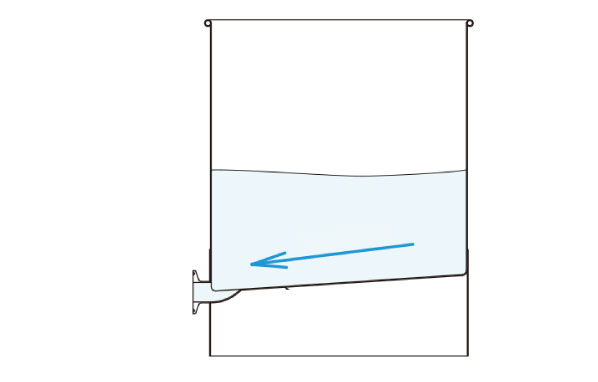

Storage and discharge container with inclined bottom plate.

An airtight container that can be easily sealed with a clip.

○Since the bottom plate is inclined in the discharge direction, all liquid can be discharged.

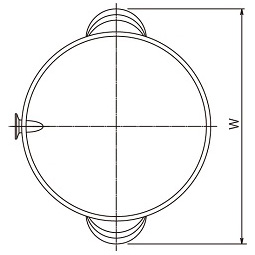

○Since the discharge port is attached to the side of the container, the piping can be rotated quickly.

○The packing is made of silicone rubber which complies with the Food Sanitation Law.

○It is made of a thin plate with a thickness from t 1.0 to t 2.0 and can be easily handled when moving or cleaning containers.

○The corner of the bottom has an R-structure that prevents dirt from accumulating.

○Liquid can be sent by connecting a pump.

Price:

Click here to purchase

Product Introduction Video

Product Specifications

Container Body/Hakama ... SUS 304

Lid [MF] ... SUS 304

Handle ... SUS 304

Catch Clip ... SUS 304

Packing [PQA/PQB] ... Silicon Rubber (Food Sanitation Law Compliant Product)

*Type A packing [PQA] is supplied with KTT-CTH -30 to 47 H, and type B packing [PQB] is supplied with KTT-CTH -565 and above.

●Surface Treatment: Inner and Outer Surface 0.2Ra

●Conditions of use: atmospheric pressure (Do not pressurize or decompress.)

Capacity: 20 L, 25 L, 35 L, 45 L, 65 L, 80 L, 100 L, 150 L, 200 L, 300 L, 400 L, 500 L, 750 L, 1000 L

Other capacities are available by special order, so please contact us.

*Can be placed on a container carrier [KM Series].

For details, see POINT "List of types of containers and bogies".

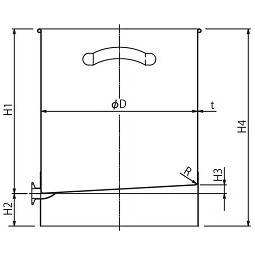

Reference Dimensional Drawing

Model # List

| Model | Capacity | Weight | Diameter | Internal Height | DrainHeight | HeightDifference | Inclination | Overall Height | Overall Width | Drain | BottomRound | Plate Thickness | RoHS | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | kg | D | H1 | H2 | H3 | Angle | H4 | W | Size | R | t | Days | ||

| KTT-CTH-30 | 20 | 6 | 300 | 320 | 75 | 20 | 4° | 395 | 380 | 1S | 5 | 1.0 | Compliant | 2 |

| KTT-CTH-33 | 25 | 7 | 330 | 350 | 75 | 20 | 3° | 425 | 436 | 1S | 5 | 1.0 | Compliant | 2 |

| KTT-CTH-36 | 35 | 8 | 360 | 380 | 75 | 20 | 3° | 455 | 469 | 1S | 5 | 1.0 | Compliant | 2 |

| KTT-CTH-39 | 45 | 9 | 387 | 420 | 75 | 20 | 3° | 495 | 496 | 1S | 5 | 1.0 | Compliant | 2 |

| KTT-CTH-43 | 65 | 11 | 430 | 480 | 80 | 20 | 3° | 560 | 548 | 1S | 5 | 1.0 | Compliant | 2 |

| KTT-CTH-47 | 80 | 15 | 470 | 500 | 85 | 20 | 2° | 585 | 592 | 1S | 5 | 1.2 | Compliant | 2 |

| KTT-CTH-47H | 100 | 16 | 470 | 620 | 85 | 20 | 2° | 705 | 592 | 1S | 5 | 1.2 | Compliant | 2 |

| KTT-CTH-565 | 150 | 20 | 565 | 650 | 90 | 30 | 3° | 740 | 690 | 2S | 5 | 1.2 | Compliant | 2 |

| KTT-CTH-565H | 200 | 25 | 565 | 930 | 90 | 30 | 3° | 1020 | 690 | 2S | 5 | 1.2 | Compliant | 2 |

| KTT-CTH-635 | 300 | 37 | 635 | 1030 | 90 | 30 | 3° | 1120 | 750 | 2S | 15 | 1.5 | Compliant | 25 |

| KTT-CTH-77 | 400 | 56 | 770 | 930 | 90 | 30 | 2° | 1020 | 887 | 2S | 15 | 2.0 | Compliant | 30 |

| KTT-CTH-77H | 500 | 64 | 770 | 1130 | 90 | 30 | 2° | 1220 | 887 | 2S | 15 | 2.0 | Compliant | 30 |

| KTT-CTH-100 | 750 | 93 | 1000 | 1080 | 90 | 50 | 3° | 1170 | 1119 | 2S | 20 | 2.0 | Compliant | 30 |

| KTT-CTH-100H | 1000 | 108 | 1000 | 1390 | 90 | 50 | 3° | 1480 | 1119 | 2S | 20 | 2.0 | Compliant | 30 |

| Unit of length is mm. | ||||||||||||||

Details & Notes

Available to products made of SUS316L material!

The standard material for Nitto Kinzoku is SUS304.

SUS316L is a material with higher corrosion resistance than SUS304.

It contains an ingredient called “molybdenum”, which is not contained in SUS304.

This molybdenum makes the passive film thicker and improves the corrosion resistance.

SUS316L is a low-carbon type stainless steel with a low carbon content, and is resistant to corrosion (intergranular corrosion) in the welding area where parts are connected to each other.

SUS316L is generally recognized as a high-grade model of stainless steel material.

It is a material that is commonly used in production sites in the pharmaceutical industry.

If you are concerned about rust and corrosion resistance, we recommend you to select SUS316L.

For more details, please contact us.

Q&A

- Q Can I change the material of the container?

- Acan. There is SUS316L.

- QOr packing there is a material other than silicon?

- AThere is also a material such as fluorine rubber.

- QI corrosion resistance of need ...

- AThere is also a surface treatment of the fluorine resin coating.

- QDo you Doren'nozuru is can be changed?

- ASize difference or nipple, you can change the socket or the like.