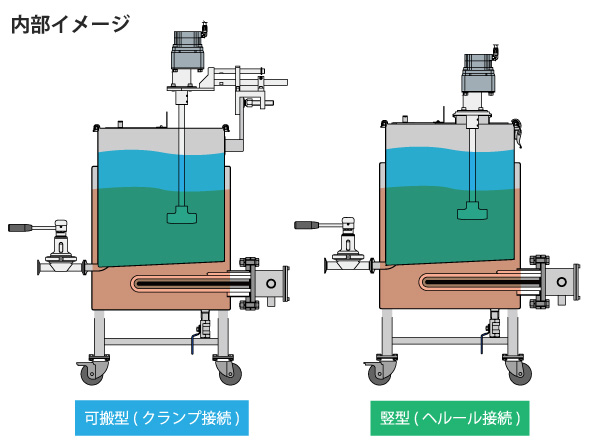

KHU: A heater unit with a Bernoulli’s stirrer

Features

High power with high power rising time!

A stirring temperature unit that allows you to warm the contents evenly in a short time.

Stainless steel containers, heaters, stirrers, and valves are set.

○ The content is indirectly warmed up with a hot water supply method to prevent burns.

○ By heating while stirring, the content can be heated evenly.

○ The temperature can be raised to up to 80 ° C.

○ The stirrer adopts a "Bernouy stirrer", which is excellent in stirring with a low foaming.

○ Compared to Chiller (constant temperature water circulation device), the feature is that the temperature is quicker, cheap, and compact.

○ The temperature of the contents can be adjusted by linking the thermometer and the heater.

○ Includes a level meter that allows you to check the water level in the jacket.

See examples of adoption of this product

Click here to purchase

Product Specifications

[Container body]

Material ... SUS304

Packing material: Silicon rubber (Food Sanitation Law Compatible)

Caster material ... SUS+urethane car (2 with inner stopper)

Surface treatment ... Inner and outer buff polishing

Usage conditions: Attotive pressure (non -reduced voltage is not allowed)

Valve ... LPS valve

[mixer]

Liquid part material ... SUS316 or 316L

Rotation speed ... maximum 800 or 1050rpm

Vertical stirrer connection part ... 4.5S Helle

* The specifications of the stirrer vary depending on the model.

For more information, see each detail page.

List of stirring machines

[heater]

Used temperature range ... normal temperature ~ 80 ° C

Output ... 7.5kw

Power supply ... 3 phase 200V (wiring and plug separately)

Body material ... SUS316L

Cover material ... SUS304

An empty heating prevention function ( * In the unlikely event that it is fired, it is a safety function to prevent accidents such as fire. )

Reference Dimensional Drawing

Details & Notes

| Model | Container size | capacity | Inner diameter | Jacket inner diameter | Container height | Drain | Number of legs |

|---|---|---|---|---|---|---|---|

| L | D1 | D2 | H | size | |||

| KHU-KTT-J-L- [stirrer] -43 | 43 | 65 | 430 | 470 | 880 | 1s | 4 |

| KHU-KTT-J-L- [stirrer] -47 | 47 | 80 | 470 | 565 | 900 | 1s | 4 |

| KHU-KTT-J-L- [stirrer] -47h | 47H | 100 | 470 | 565 | 1020 | 1s | 4 |

| KHU-KTT-J-L- [stirrer] -565 | 565 | 150 | 565 | 635 | 1050 | 2s | 4 |

Case Studies

Example of adoption by a surfactant manufacturer

Application: Wax melting and heat insulation

ECK: Adding a heat-insulating cover improves the heat-retaining effect and helps prevent burns on workers.

Example of use by a chemical manufacturer

Application: Dissolution of binder solution

The dissolution time is shortened by heating directly with a throw-in heater instead of using a jacket.

Other customers include food (soybean processing) manufacturers, health food manufacturers, and semiconductor equipment manufacturers.

Q&A

- QCan the capacity change?

- AIs possible. We will respond by changing the height of the container.

- QIs it possible to order a non -stirrer and design according to the stirrer or a stirrer on hand?

- AIs possible. It is smooth if you send the drawing of the desired stirrer.

- QIs it possible to customize the stirrer or container? (Adding a joint, surface treatment, packing material change, etc.)

- AIs possible. Please let us know the application and desired specifications. It is smooth if you can get simple illustrations and drawings. Click here for examples of custom products