Craft Beer Conical Set

Features

Set of stainless steel tanks designed for the "saccharification, boiling, and fermentation" processes of beer brewing.

Fermentation tanks are conical type for easy extraction of yeast.

We can manufacture tanks with desired capacities from 100L to 1000L.

Compact design that requires little installation space, making it suitable for small breweries such as those attached to stores.

Equipped with a scale and a level gauge to check the content volume.

Customization (optional processing) is available to suit your needs. See examples of optional modifications

Other peripheral equipment can be arranged. (Chiller/heat exchanger/pump/hose, etc.)

Click here to purchase

Product Specifications

Vessel body and base Material: SUS304

Fermentation tank pressure resistance (inner and outer tanks: 0.15 MPa)

Reference Dimensional Drawing

Details & Notes

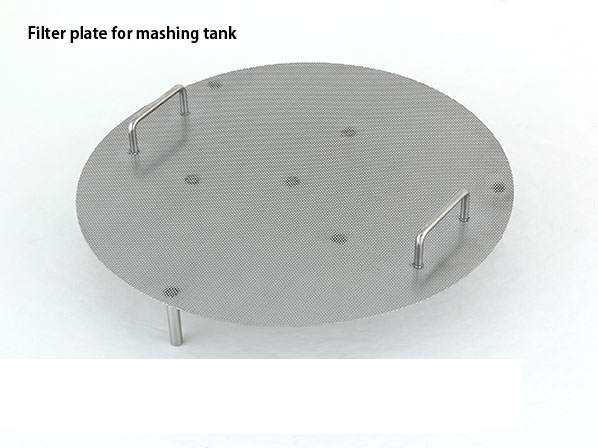

Mash Tun

This tank is used for wort preparation from saccharification to filtration. It comes with a thermometer for temperature control and a mesh bottom plate to prevent malt from accumulating at the bottom.

Brew Kettle

This tank is used to boil filtered wort along with hops. It is an open tank with a lid and nozzle.

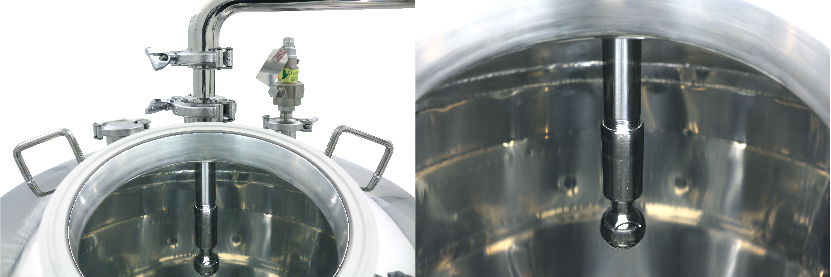

Fermentor

Conical-type tanks allow for easy collection of yeast and a three-tank structure for stable fermentation.

Water is circulated through the outer tank at a controlled temperature by a chiller or other means to maintain the temperature of the contents at a constant level.

A rotating racking arm is used at the outlet to minimize sediment contamination.

Includes a shower bowl to rinse out the tank

Peripheral equipment is also available.

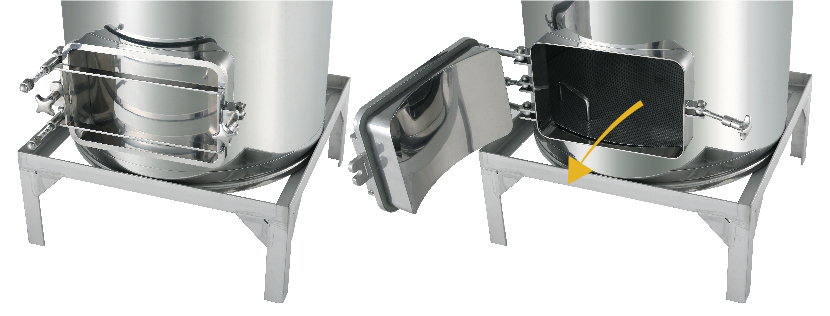

Example of tank customization

- Added a cleaning port (for malt discharge) to the mashing tank

- Saccharification tank: Change the loiter plate to a slit hole.

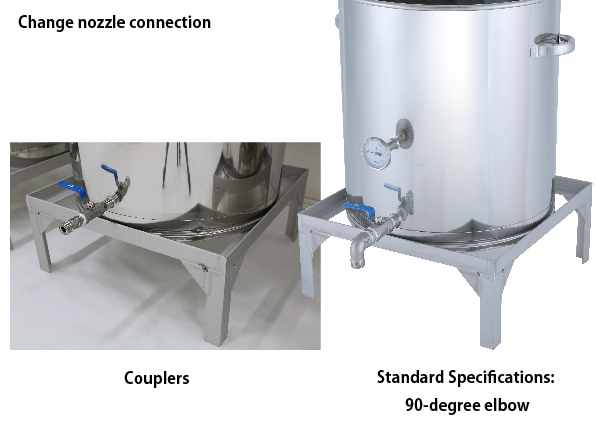

- Change of outlet port (change to “coupler” for easy connection and disconnection, etc.)

- Additional Marking: Tanks can be marked with text. Logos, etc. can also be added, so please consider this option for installation in blue pubs.

Recommended Optional Parts

”Hose bracket” for securing transfer hoses