CTH-STA : Stackable Sealed Container

Features

Clip type sealed container that can be stacked in multiple stages (stacking).

○Stackable (stacking) by adding steps to the bottom itself.

○The bottom and clip can be stacked without interference, saving space.

○Since multi-layer hakama [H] is not attached, foreign matter and cleaning liquid do not accumulate on the outer surface and it is hygienic. In addition, it is 11% lighter on average than the case where a multi-layer hakama is attached.

○Sealed container prevents scattering of contents and dust from entering from outside.

Price:

Click here to purchase

Product Specifications

The container body, lid, handle catch clip ... SUS304

Packing ... silicon rubber ([PQA]) (Food Sanitation Law compliant products)

● Surface treatment: the inner and outer surfaces buffing

● use conditions: atmospheric pressure (pressurization and depressurization is impossible)

Capacity: 10L, 20L, 36L, 65L

※ other capacity are also available (special order)

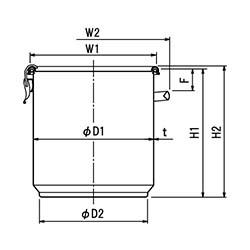

Reference Dimensional Drawing

Model # List

| Model | Capacity | Weight | Diameter | Diameter | Container Height | Overall Height | Outer Diameter | Maximum Width | Handle Height | Clip | Plate Thickness | Gasket | RoHS | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | kg | D1 | D2 | H1 | H2 | W1 | W2 | F | Quantity | t | Days | |||

| CTH-STA-24 | 10 | 2.2 | 240 | 210 | 262 | 269 | 254 | 315 | 41 | 3 | 0.7 | A-type | Compliant | 2 |

| CTH-STA-30 | 20 | 3.3 | 300 | 270 | 322 | 328 | 316 | 380 | 56 | 3 | 0.8 | A-type | Compliant | 2 |

| CTH-STA-36 | 36 | 5.3 | 360 | 330 | 382 | 388 | 378 | 469 | 52 | 4 | 0.9 | A-type | Compliant | 2 |

| CTH-STA-43 | 65 | 8.2 | 430 | 400 | 472 | 478 | 452 | 548 | 82 | 4 | 1.0 | A-type | Compliant | 2 |

| Unit of length is mm. | ||||||||||||||

Details & Notes

What is the difference between stacking and nesting?

Stacking Container

It is a way of stacking containers on top of each other.

Stackable containers make effective use of space when storing or moving.

Nesting Container

It is a way to put a container in a container and store it.

Nestable containers can be stored compactly without taking up space when storing empty containers.

a container capable of nesting

[TP-CTH-STA] Stackable Tapered Sealed Container

Space-saving stainless tank for stacking and nesting storage.

Available to products made of SUS316L material!

The standard material for Nitto Kinzoku is SUS304.

SUS316L is a material with higher corrosion resistance than SUS304.

It contains an ingredient called “molybdenum”, which is not contained in SUS304.

This molybdenum makes the passive film thicker and improves the corrosion resistance.

SUS316L is a low-carbon type stainless steel with a low carbon content, and is resistant to corrosion (intergranular corrosion) in the welding area where parts are connected to each other.

SUS316L is generally recognized as a high-grade model of stainless steel material.

It is a material that is commonly used in production sites in the pharmaceutical industry.

If you are concerned about rust and corrosion resistance, we recommend you to select SUS316L.

For more details, please contact us.

Q&A

- QIs there an upper limit of the number of stacks?

- ASince it depends on the size and usage does not set in our company. Please be stacked to the extent that safety and stability can be ensured.

- Q(The put container in a container) is or can be nested storage?

- AFor straight container, it can not be stacked in nested. You can When was stacked type taper sealed container [TP-CTH-STA].

- QBut we want to increase the tightness ....

- AAnd how to increase the number of clips, there is a way to use the pressure vessel. Please contact us for more information.

- QIs it possible to change the handle?

- AYou can change the handle of the type and mounting position.

- QIs there any way to not stepped on the bottom?

- AI attached to the outer surface of the multi-stage Sekihakama [H].