Stainless steel tank for solvent cleaning with exposure measures

Features

Case Example in the Chemical Industry

This is an example of a custom-made stainless steel tank used for cleaning parts with organic solvents.

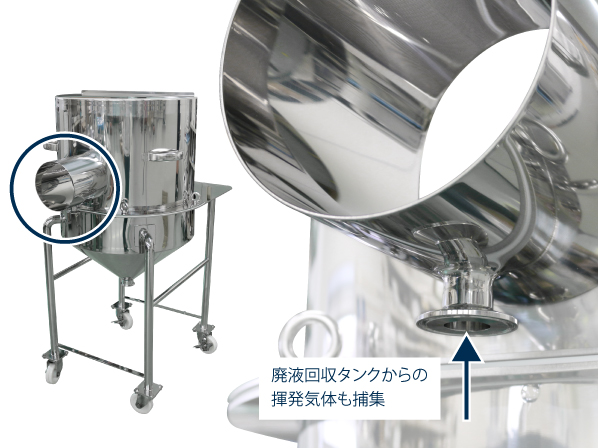

The tank is a hopper type that allows waste liquid after washing to be discharged from the bottom, and the hood at the top collects volatile gases (solvent gas) to reduce exposure to the workers.

Point

- Volatile gases are collected from the nozzle at the back of the hood. The nozzle at the bottom of the hood is connected to the liquid waste collection tank and collects volatile gases from there as well.

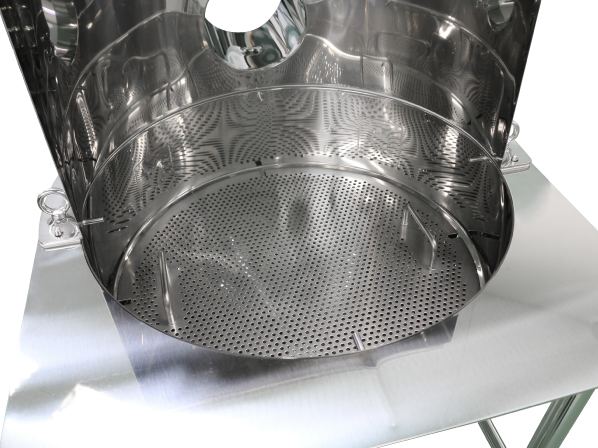

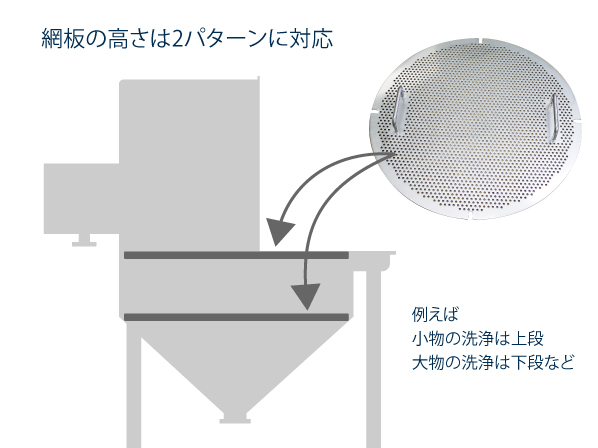

- The position (height) of the perforated plate on which the parts to be cleaned are placed can be changed according to the size of the parts.

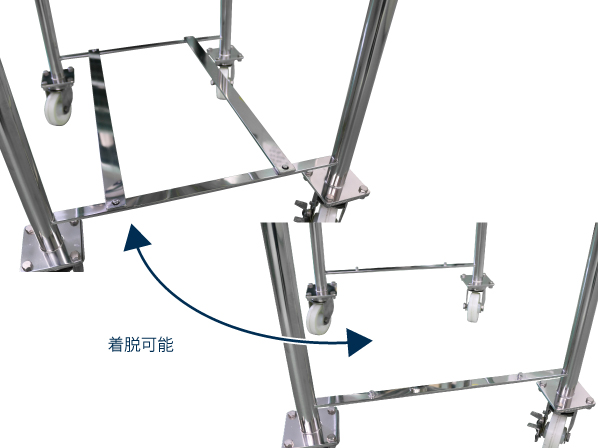

- There is a removable board between the legs on which a liquid waste collection tank or bat can be placed.

- Casters are selected from solvent-resistant materials.

Sales Comment

Although the base product was designed for dust collection, the gas collection application has also contributed to the improvement of the working environment.

Engineering comment

Considering the specific gravity of volatile gases, the nozzle of the hood was installed as low as possible. The nozzle is designed to match the hose diameter provided by the customer.

Product Specifications

| container material | SUS304 |

|---|---|

| caster material | nylon |

| Dimensions | Container Inner diameter φ565mm x total height 1280mm |

| Surface treatment | Inner and outer buff polishing |

| Management number | 1Y007212-1 |

Details & Notes

Customization based on existing products

The original product is designed for dust collection purposes, but customization tailored to customers’ needs, such as gas collection applications, is possible for individual items.

There are also products with only a dust collection hood that can be used in combination with existing tanks. These can also be customized.