Agitation unit for in-house resin dilution

Features

Example of adoption in the chemical industry

A 300L capacity agitation unit combining a stainless steel tank and an agitator used in the process of diluting resin materials with a solvent.

Customer's problem

Small quantities are mixed manually with a spatula or outsourced. Human labor is time-consuming and labor-intensive, and outsourcing cannot be requested unless the number is large enough.

Tailor-made services for in-house production

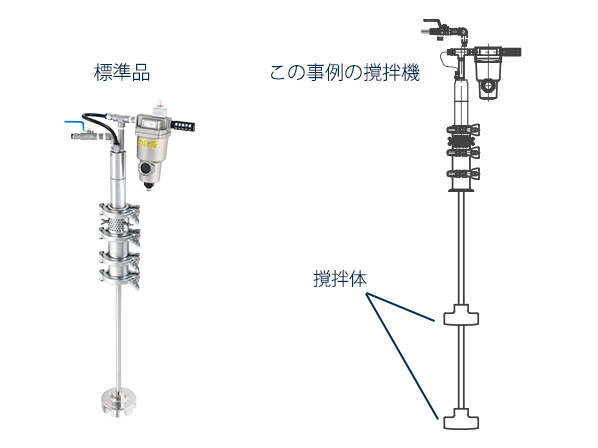

- To be able to handle a wide variety of resin materials and solvents For the gaskets of the wetted parts, chemical-resistant materials such as PTFE and Perfluoro were adopted. In consideration of the viscosity and capacity of the contents, the agitator is installed in two stages to improve agitation.

- 「To allow discharge of even viscous resins." A single-tapered vessel is adopted. The bottom of the vessel is normally inclined at a 3° angle, but this time it was made at a 5° angle for improved discharge.

- 「Labor-saving feeding of materials into one-litre cans. The hopper at the inlet is shaped so that a one-ton can can be placed on sthe hopper, allowing the operator to remove his/her hand from the hopper when feeding the materials in the one-ton can.

Others

Other

- Adopts a valve that is easy to disassemble and clean.

- A Y-shaped strainer is installed at the discharge port as requested by the customer.

- The tip of the outlet is designed to fit into a 1-ton can for final discharge into a 1-ton can.

- Bracket (fork seat) is installed so that the tank can be lifted by a lifter.

Although the specifications are different, a 45L capacity agitation unit was also adopted at the same time.

Technical comment

To withstand the load of handle rotation when opening and closing the valve, the drain port has been reinforced and a support base has been installed at the piping section.

Product Specifications

| container material | SUS304 |

|---|---|

| Dimensions | Inner diameter φ770mm x total height H1295mm (excluding stirrer) |

| capacity | 300L |

| Surface treatment | Inner and outer buff polishing |

| stirrer | < "> Stainless steel motor stirrer [NTMA-S] |

| Management number | 1Y003766-1 |

Details & Notes

Base Products for Customization

“Industry-specific Adoption Cases” for Those Interested in Similar Industry Examples

We have received adoption of Nitto Kinzoku Kogyo’s stainless steel containers from various manufacturers in different industries. We have showcased some of our past customized cases categorized by industry.