Adoption Case : Powder Metering and Inversion Feeding Unit

Features

○Food Industry Adoption Case

Powder Metering and Feeding Unit

This unit is used for measuring and feeding powdered ingredients in the confectionery industry. It is used in the process of measuring and feeding powdered materials into a sieve.

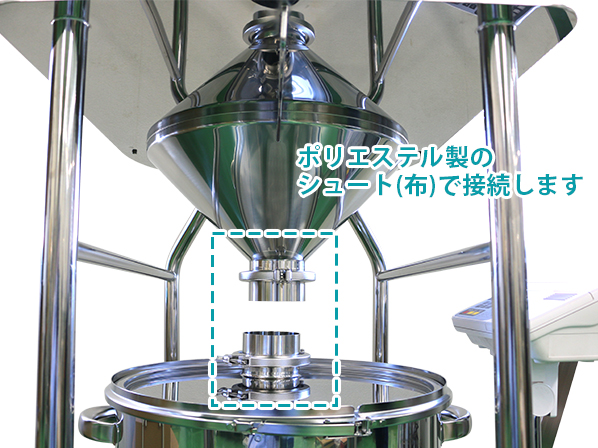

The set includes a hopper with a dust collection hood, a dust collector, a receiving container, a scale, a cart, a lid for inversion feeding, and a lifter. The dust collection hood is connected to the dust collector to collect the powder that becomes airborne during the feeding process. The hopper and receiving container are connected with polyester chutes (fabric).

The scale has a stainless steel cover and a receiving tray installed on the weighing platform. The bottom of the receiving container has an air inlet for inversion feeding.

Usage:

The materials are fed into the hopper with the dust collection hood.

The accumulated materials in the bottom receiving container are measured using the scale and then stored.

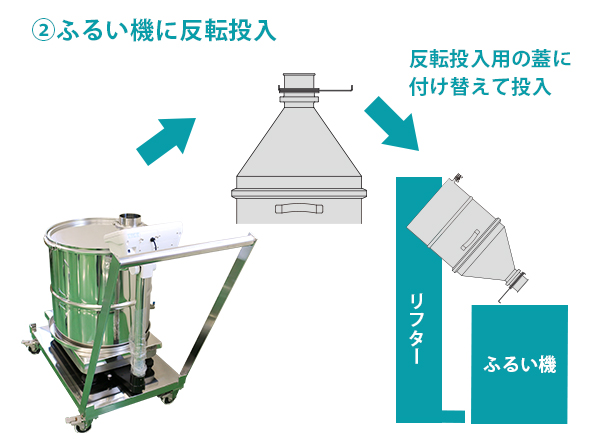

The lid of the receiving container is replaced with the lid for inversion feeding (with a valve).

The lifter is used to invert the receiving container, and the materials are fed into the sieve.

Sales Representative Comment:

This was a case of introducing the unit in a newly established factory. The customer requested an all-stainless steel construction. We were able to propose and adopt a solution within their budget, providing stainless steel hoppers, dust collectors, containers, and lifters.

Product Specifications

Specifications:

Hopper, Receiving Container, Cart Material: SUS304

Dust Collector, Lifter: Stainless steel

Hopper Dimensions: Width 580mm × Depth 850mm × Height 1567mm

Container Dimensions: Inner Diameter 470mm × Height 468mm (without lid)

Management Number: 1X011764

Unit Contents:

Hopper with Dust Collection Hood:

Based on HTD-L model, the hopper height was reduced to ensure sufficient height below while maintaining overall height.

Dust Collector:

Stainless steel construction.

Receiving Container:

Based on CTL-R model, ribs processed at one location, vent valve installed at the bottom, lid with added ferrule.

Lid for Inversion Feeding (with Valve):

Lid: Based on HTL-F-47 model, discharge port changed to 100A ferrule, hopper angle changed to 70°.

Valve: SH-100A model adopted.

Scale:

Stainless steel weighing tray.

Cart/Lifter:

Stainless steel construction.