Case Study : Powder Cleaning Unit

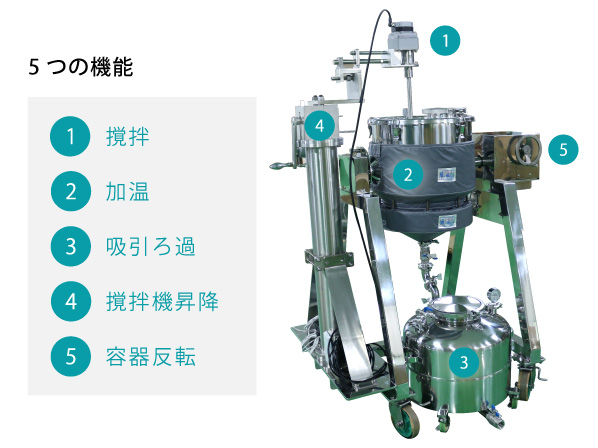

Features

Chemical Industry Case Study -

Powder Cleaning and Mixing Unit

This is a case study of a powder cleaning and mixing unit adopted in the chemical industry.

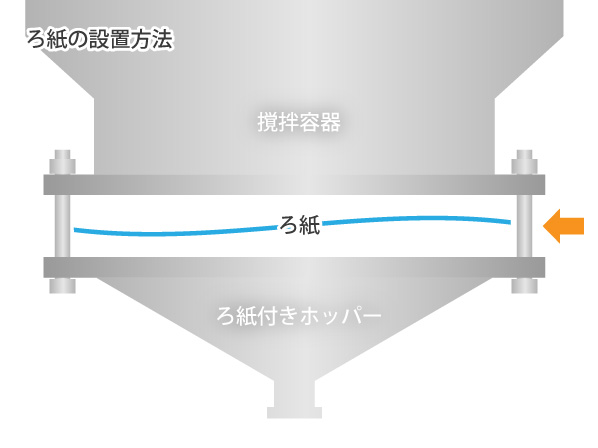

The unit is designed to separate and collect the powder and solvent, allowing for the installation of filter paper.

By loosening the connecting bolts of the hopper with the filter paper, the filter paper can be placed in the gap.

The overall height of the unit is kept at 1,800mm to facilitate easy removal and installation of the powder collection container and mixing machine.

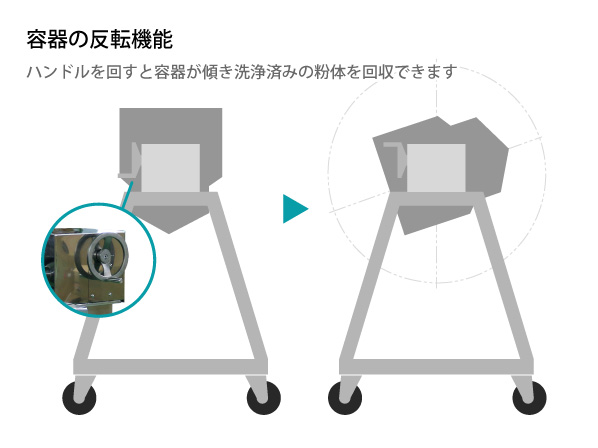

The platform is equipped with a container inversion and mixing machine lifting function.

By consolidating the functions into one unit, it minimizes the movement of the operator.

Usage:

1, Cleaning the powder

Heat and mix the powder and solvent in the upper mixing container.

A mantle heater wrapped around the container is used for heating.

2, Solvent recovery

Use suction filtration to collect the solvent into the lower waste container.

The powder remains in the mixing container, retained by the filter paper installed in the container.

3, Repeat steps 1 and 2 several times.

4, Powder collection

Tilt the container and collect the cleaned powder from the lid.

Product Specifications

Container Material: SUS304

Capacity: 50L for both the mixing container and the collection container

Mixing Machine: NTME-A-PO-E99

Mixing Machine Material: Shaft - SUS316, Mixing Body - SUS316L

Power Supply / Motor Output: Single-phase 100V / 200W

Total Height: 1,800mm (including casters to the top of the mixing machine)

Management Number: 1X002137