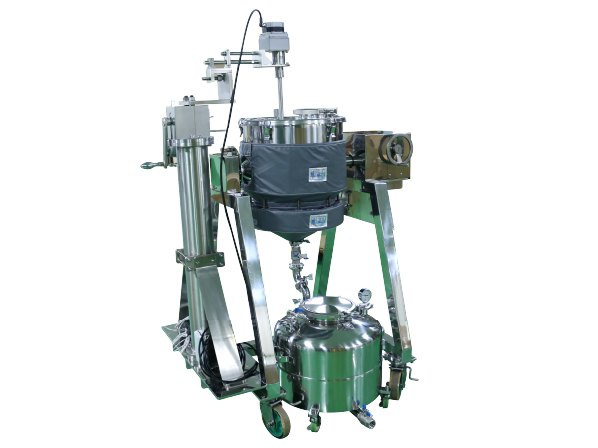

powdered cleaning unit

Features

" ○ Chemical industry recruitment case

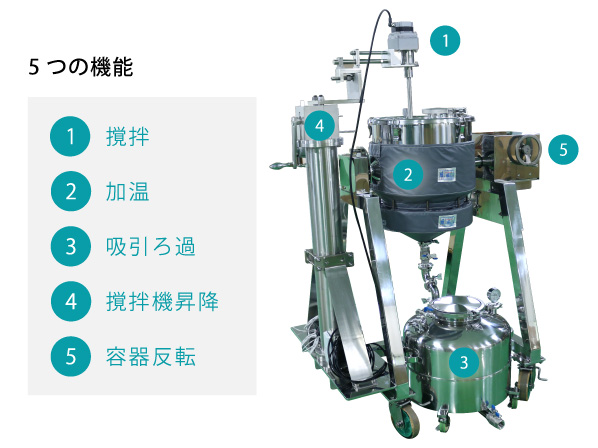

A stirring temperature unit for powder cleaning.

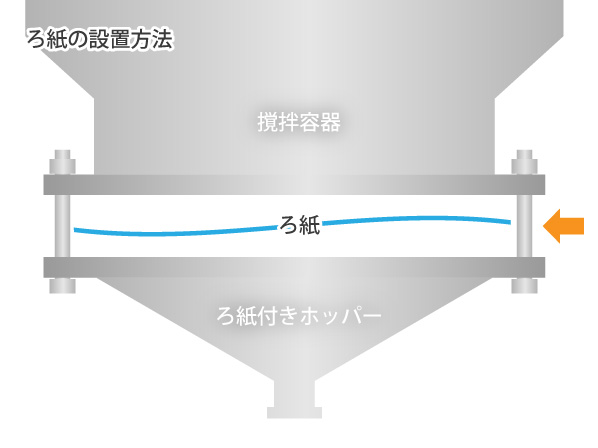

It is a structure that can be installed in a separate powder and solvent. Loosen the connection bolts of the hopper with filter paper and install the paper in the gap.

The overall height is reduced to 1,800 mm so that it is easy to attach and detach the powdered body after cleaning. The gantry has a container reversal and a stirrer lifting function.

Since the function is summarized in one, the worker moves less.

How to use

Wash the powder

The powder and solvent are heated and stirred in the upper stirring container.

For heating, a mantle heater wrapped around the container is used.

Collect the solvent Only the solvent is collected in the deserted container at the lower part by suction filtration.

The powder remains in the stirring container by the paper installed in the stirring container.

1.2. Repeat several times

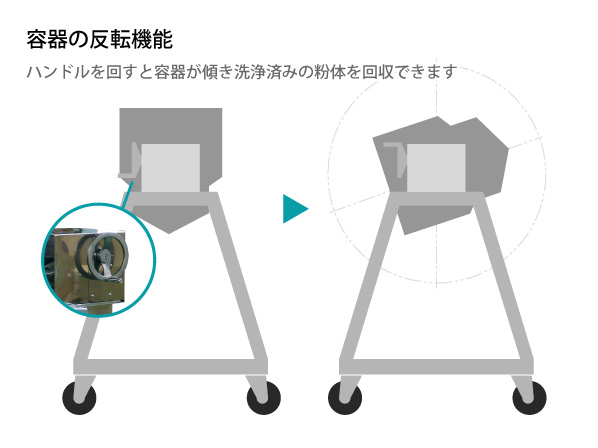

Collect the powder. The cleaning powder remaining in the stirring container is tilted and collected from the lid.

"

Product Specifications

"

container material SUS304

Capacity 50L for both the stirring container and the collection container

stirrer ntme-a-po-e99

stirrer material shaft SUS316, stirring body SUS316L

Power/Motor Output Single -phase 100V/200W

Fully 1,800mm (casters -upper part of the stirrer)

Management number 1x002137

"