Fork seated coating container

Features

Chemical manufacturer delivery

○ Customized stainless container customized cases that are customized to handle.

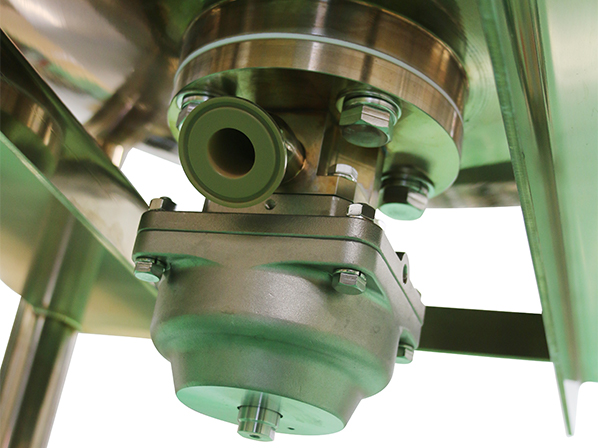

It is manufactured based on the Kakuhan Corptor Backboard Container (Tank Bottom Valve) [DTM-77].

In order to increase chemical resistance, fluorine resin coating is applied to the tank inner surface and the diaphragm valve.

Customer We install the Kakhan Corre to set up a stirrer.

The caster, suspension lug (lifting bracket), fork locus (forklift bracket) is attached to be easy to handle the tank movement.

This folk seat has made a simple specification to reduce costs, but it is also possible to install a box-shaped seat at the bottom.

Product Specifications

Dimension φ770mm × H1390mm

Total capacity 370L

Material SUS304

Surface treatment PFA300 μm coating (color: beige)

Other tank bottom valves (automatic)

Management number 1T003225 FB # 24

Details & Notes

There is a “Kakhan Corptor Plate-type Container (Tank Bottom Valve) DTM-77” as a related product of this order-made case.

In addition, fluorocarbon resin coatings are also available as option processing.View Product DetailsView Product DetailsCustom-made case that adopted fork seatView Product DetailsView Product DetailsView Product DetailsThere are various custom-made cases

The Nitto Metal Industries produces various stainless steel products as ordered.

Some of the past results can be searched by industry-by-shape and use.

Please feel free to contact us for custom-made production.

[ONE_HALF]

Search for custom-made cases

[/ONE_HALF] [ONE_HALF_LAST]

Talk about custom made

[/ONE_HALF_LAST]

Technology column that understands the features of fluorine resin coatings

Fluorocarbon resin coatings to stainless steel containers are introduced in the following two columns.Technology column “Everybody minded, no fluorine resin coating-7 features-”

See this column

Technology column “The weakness of fluorine resin coating!? None of pinhole I want to be careful”

See this column