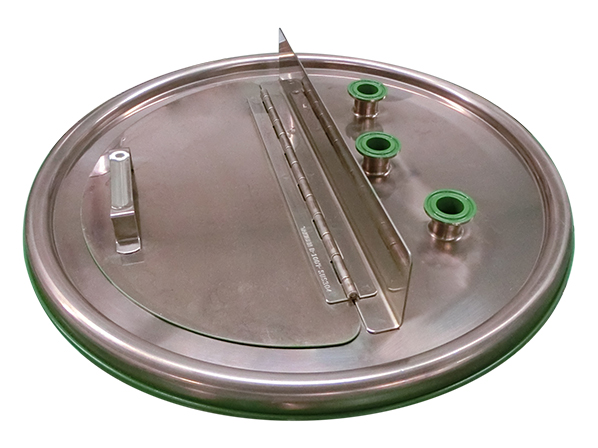

Raw material input hopper (inner coating)

Features

Food manufacturing maker delivery

○ Custom-made cases of stainless steel hopper container used for raw material input of the ground beer production process.

The inner surface is subjected to fluorocarbon resin coating to improve cleanability and slippability.

The knocker is attached to the bottom of the hopper so that the raw material does not remain.

The lid adopts an open / close lid that can easily introduce and confirm the contents.

Product Specifications

Dimensions inner diameter φ360 mm × total high H1000 mm

Capacity 30L

Material SUS304

Surface treatment outer surface: # 320 buff polishing

Interface: ETFE 300 μm (green) coating

Bond thickness T1.2mm

Parts knocker seat, knocker, vent tube

Management number 1Q000740

Details & Notes

There is a “hopper-type closed container leg clip” as a product based on this order-made case.

In addition, fluorocarbon resin coatings are also available as an optional process of stainless steel containers.

We also manufacture a stainless steel tank for beer brewing.View Product DetailsView Product DetailsCustom-made case with fluorine resin coating

Fluorocarbon resin coatings can select specifications according to content and applications such as improvement in chemical resistance and improvement of slippability.View Product DetailsView Product DetailsView Product Details

View Product DetailsView Product DetailsView Product DetailsThere are various custom-made cases

The Nitto Metal Industries produces various stainless steel products as ordered.

Some of the past results can be searched by industry-by-shape and use.

Please feel free to contact us for custom-made production.

Talk about custom made

Search for custom-made cases

Technology column that understands the features of fluorine resin coatings

Fluorocarbon resin coatings to stainless steel containers are introduced in the following two columns.Technology column “Everybody minded, no fluorine resin coating-7 features-”

See this column

Technology column “The weakness of fluorine resin coating!? None of pinhole I want to be careful”

See this column