R/RF : Rib Machining

Features

It is an optional processing mainly for lifting and reversing stainless steel containers with a lifter.

In some cases, it is used to reinforce the container or to process the lid to prevent the hose or chute from coming off.

What's a rib?

・It is also called "beat" or "braiding" which is a processing to make the side of the container uneven.

・It is used to prevent the container from falling when lifting or reversing with a lifter, and to improve the strength of the container.

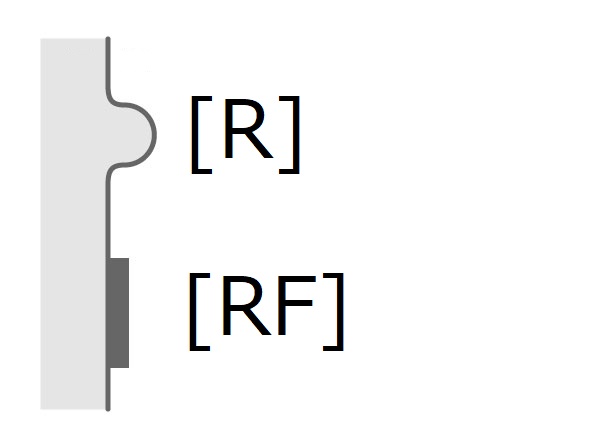

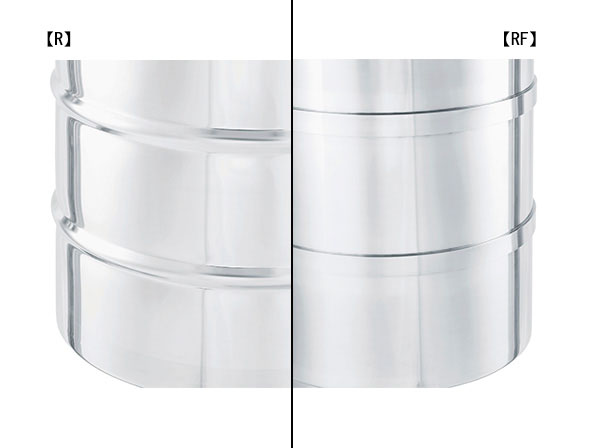

There are two types of rib specifications.

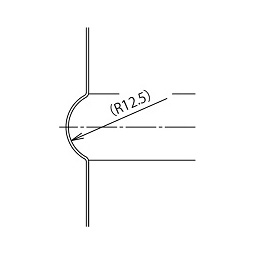

・With drawstring [R]: Rib processing often seen in drum cans. The weight of the container does not change because the rib is produced by molding the container itself.

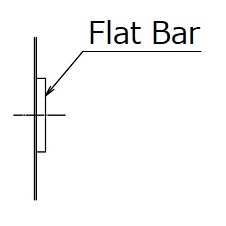

・Flat bar specification [RF]: Rib processing to wind the flat bar around the outside of the container and attach it by welding. As the inner surface of the container is flat without dents, powder does not accumulate.

Click here to purchase

Product Specifications

Optional processing of stainless steel containers made by Nitto Metal Industry.

The rib spacing can be set to any value.

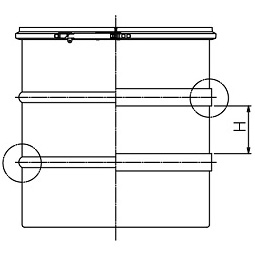

Reference Dimensional Drawing