CTH-EP : Electrolytically Polished Stainless Steel Sealed Container

Features

Stainless steel container with internal electrolytic polishing treatment.

Can be easily sealed with clips.

The inner surface of the container is electrolytically polished.

Because dirt such as buffing powder is removed, cleaning costs before use can be reduced.

Since the surface becomes smooth, it is hard to get dirty and has excellent cleaning properties.

Strong passive film is formed by electrolytic polishing, improving corrosion resistance.

Sealed type to prevent scattering of contents and contamination of dust.

Price:

Click here to purchase

Product Specifications

Container [CTH] ... SUS 304

Packing ... Silicon Rubber (Food Sanitation Law Compliant Product)

Surface treatment: internal electrolytic polishing after internal and external buffing

Conditions of use: atmospheric pressure (Do not pressurize or decompress.)

Capacity: 7 L, 10 L, 20 L

*Other sizes are also available.

This product is manufactured in hermetically sealed containers (catch clip type) [CTH].

Electrolytic polishing is applied to the inner surface.

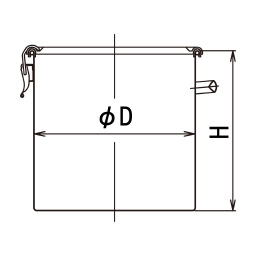

Reference Dimensional Drawing

Model # List

| Model | Capacity | Weight | Diameter | Internal Height | Clip | Plate Thickness | Gasket | Gasket | Lead Time |

|---|---|---|---|---|---|---|---|---|---|

| L | kg | D | H | Quantity | t | A-type | B-type | Days | |

| CTH-21-EP | 7 | 1.6 | 210 | 210 | 3 | 0.7 | ● | ○ | 2 |

| CTH-24-EP | 10 | 2.1 | 240 | 240 | 3 | 0.7 | ● | ○ | 2 |

| CTH-30-EP | 20 | 3.2 | 300 | 300 | 3 | 0.8 | ● | ○ | 2 |

| Unit of length is mm. ●is standard, ○ is optional. | |||||||||

Details & Notes

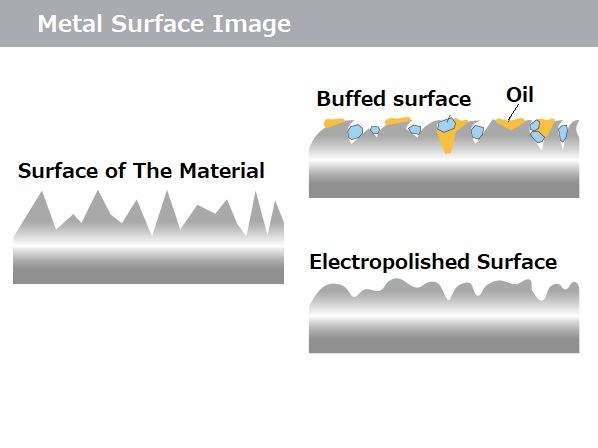

Features of Electrolytic Polishing

(1)cleaning effect

It can remove foreign objects such as buffing powder and oil that are difficult to remove with normal cleaning methods.

Even if the machine-polished or buffed surface looks clean, it is a collection of fine scratches, and foreign matter such as oil or buffing powder embedded in these scratches cannot be removed by cleaning.

(2)Improvement of Washability

Since it has a very smooth surface, dirt and other substances do not easily deposit and cleaning becomes easy. In the same way, it is hard to get rust.

(3)Improved corrosion resistance

In the case of stainless steel, the concentration of chromium on the metal surface increases as iron ions dissolve first, and a stronger passive film is formed.

It is believed that stainless steel does not rust easily because chromium contained in stainless steel is oxidized and passivated.

(4)there’s very little elution of ions from the surface.

Metal ions such as iron are difficult to elute from the passivated metal surface.

Available to products made of SUS316L material!

The standard material for Nitto Kinzoku is SUS304.

SUS316L is a material with higher corrosion resistance than SUS304.

It contains an ingredient called “molybdenum”, which is not contained in SUS304.

This molybdenum makes the passive film thicker and improves the corrosion resistance.

SUS316L is a low-carbon type stainless steel with a low carbon content, and is resistant to corrosion (intergranular corrosion) in the welding area where parts are connected to each other.

SUS316L is generally recognized as a high-grade model of stainless steel material.

It is a material that is commonly used in production sites in the pharmaceutical industry.

If you are concerned about rust and corrosion resistance, we recommend you to select SUS316L.

For more details, please contact us.

Q&A

- QDoes it come with an electrolytic polishing certificate?

- ANot included. Please let us know so that we can create if there is hope.

- QIs it possible to manufacture in SUS316L?

- AIt can be manufactured.

- QAre you under pressure?

- AYou can not pressure. Please use the pressurized vessel.

- QIs it possible to polish electrolytic other products?

- AIs possible. Please let us know the products of your choice.

- QI want to know more information about the electrolytic polishing.

- APlease see because there is technology booklet .